FORT LORAMIE — Over the course of more than 50 years, Wayne Trail has provided tooling, equipment and system solutions to markets and customers around the world. Manufacturers from a variety of industries look to Wayne Trail for innovative and dependable automated manufacturing solutions to the metal forming, fabricating, metal joining, and materials handling challenges they face.

John A. Campbell, general manager, has submitted the following report:

Wayne Trail became part of Lincoln Electric in May of 2012. Lincoln Electric is the world leader in the design, development and manufacture of arc welding products, robotic arc welding systems, plasma and oxyfuel cutting equipment – and has a leading global position in the brazing and soldering alloys market. Headquartered in Cleveland, Ohio, Lincoln Electric currently has 47 manufacturing locations, including operations and joint ventures in 19 countries and a worldwide network of distributors and sales offices covering more than 160 countries.

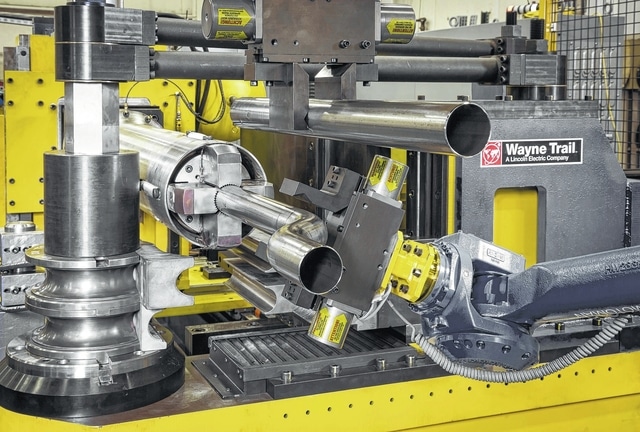

Wayne Trail’s extensive design and system building experience, proven capabilities and continued commercial success in the area of laser welding, robotic welding & fixturing systems, press automation, tube bending/fabricating systems, and aerospace tooling – further strengthens the already strong position Lincoln Electric has as the market leader in welding, cutting and related automation in North America.

The company’s customer base includes the automotive, appliance, aerospace, alternative energy, agricultural and industrial markets. Notable Wayne Trail clients and projects include the Ford Motor Company, for whom we recently provided a large automation system used to produce hydro-formed components for the F-150 truck line. Also, a notable project involving the manufacturing of hydrogen fuel cells was completed in 2015.

Also, in 2015 the Lincoln Electric Co., Cleveland, acquired all intellectual property related to laser welding and marking systems produced by Process Equipment Co. (PECo), located in Tipp City, Ohio. Wayne Trail will assume responsibility for servicing and supporting the installed base of PECo laser welding and marking systems, while also bidding on new projects utilizing this technology. Wayne Trail also has hired key PECo personnel.

Wayne Trail expects to further invest in its capabilities in 2016 as it serves the attractive aerospace, appliances and automotive industries.