RUSSELLS POINT — Students from Shelby County learned first hand what types of employees Honda of America is looking for as they prepare for the next generation of associates. The students toured the Honda Transmission Manufacturing facility in Russells Point during an extended National Manufacturing Day, which began Friday, Oct. 2, and continues this week.

More than 300 students from Sidney High School toured the facility, where they learned about robotics, electrical and maintenance of the equipment. Students from Anna, Botkins, Fairlawn and Jackson Center also toured the facility. Other schools participating in the event were from Bellefontaine, Benjamin Logan, Botkins, Indian Lake, Kenton, Ridgemont, Riverside, Triad, Upper Scioto Valley, Tri-Rivers Career Center, Ohio Hi-Point Career Center, Upper Valley Career Center, Wapakoneta and Waynesfield-Goshen. More than 1,600 students will tour the facility by the end of the week.

“We bought students from the Workforce Academy, RCI, DECA, food science, information systems, CBI and any senior who wanted to participate in the tour,” said Sidney High School Principal John Geuy.

From robotics to PLCs and electrical and pneumatics to equipment service, the students learned how the industry is continuing to change.

“As a leading company of high-quality transmissions, we take great pride in our manufacturing operations and want to share our passion with local students and the community,” said Gary Hand, vice president of Honda’s transmission plant in Russells Point. “Our goal is to inspire the next generation workforce for high-tech positions in the manufacturing industry.”

HTM associate Donovan Williams told the students he’s been with Honda for eight months. Williams said he’s still learning about Honda and how things are done at the company. He explained how a Jenga-playing robot was programmed to remove the pieces of the puzzle and how the programming can be updated if a job requirement is changed.

As the students walked through the facility the noise of the machines was highlighted by various songs. The students were told that when a machine gets ready to begin its work, a song will be played so the Honda associates know it’s time to take their safety precautions associated with the job.

Scot McLemore, who talked to students Friday, said he wants to change perceptions of how society views the manufacturing business in general and, specifically, how factories and those who work in them are viewed.

“The perception is that careers in manufacturing are undesirable and the plants themselves are dark, dirty and dingy,” said McLemore, manager of Technical Workforce Development at Honda of North America. “In fact, it’s quite the opposite. You could just look around today and see that’s not true.”

McLemore and Honda hope to see these same students back in the near future as highly-skilled technicians programming and repairing the robotics and other high-tech mechanics that are part of today’s heavy industry.

“We opened some eyes today,” McLemore said. “There are a whole host of careers that are available in the manufacturing industry. We want to show the students what is out there for them and hopefully provide them some direction.”

The 1.1 million square-foot HTM facility goes a long way to proving McLemore’s point. It’s well-lit, open, airy, free of rubbish and other detritus. HTM is in the business of casting, machining and assembling transmissions for automobiles, so it is packed full of machinery ranging from impact wrenches to a machine the size of a pole barn that heats and cuts aluminum rods to spec for the various gears produced at HTM.

Much of what lies between these two extremes are technologies – robotics, pneumatics, programming, industrial design and a host of others – that are innovating at light speed and can be found throughout the HTM campus. McLemore and Honda are looking to local high schools for their future workers who can implement or even invent these new technologies and apply them at HTM or other Honda plants.

“It’s important for us to raise the awareness of the opportunities for highly-skilled, well-paid talent that are available right here,” McLemore said. “These tours are a way for Honda to show the students what a manufacturing career looks like in 2015. We went them to make the connection where they can combine ‘high tech’ with manufacturing careers.”

“We’re looking for students who want careers where they can be innovative,” McLemore said. “Careers that pay well, careers that call for people who are continuous learners, careers where they can adapt and make changes.”

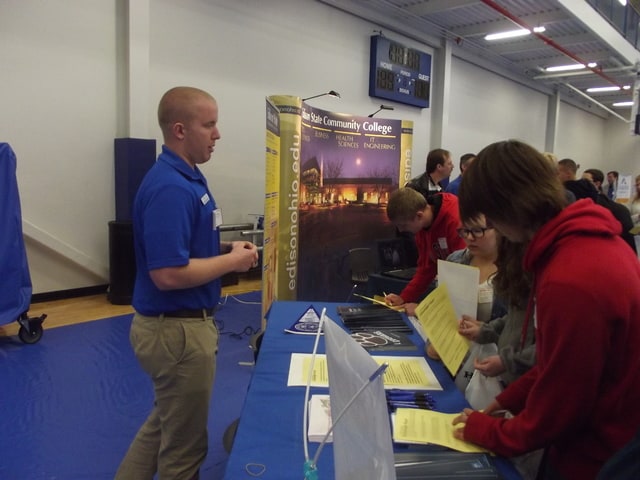

Rhodes State College was one of the colleges and career centers who participated in the career fair at the end of the tour.

Doug Durliat, director of the West Central Ohio Manufacturing Consortium, Economic Development and Continuing Education at Rhodes, said job fairs such as the one at Honda are important for them to have the opportunity to explain the school and its programs to high school students.

“This is the beginning of our outreach to students who are not aware of Rhodes State,” said Durliat. “You never know who will be enrolled in the school next year at this time.”

Durliat said the college offers many programs which fit Honda job training requirements. Some of the programs include engineering technology, manufacturing engineering and industrial manufacturing technology.

Kathy Voris, Upper Valley Career Center, said she was there to explain the adult education program to the high school students.

Megan Jett, a job recruiter for Honda, told the students that a two- or four-year college degree is an asset for an associate.

National Manufacturing Day is sponsored in part by the National Association of Manufacturers and is observed each year in October. According to National Manufacturing Day partners, an estimated 3.5 million U.S. manufacturing jobs will be needed over the next decade, and 2 million of those jobs are expected to go unfilled due to manufacturers’ inability to find employees with the required skills.

Located in Russells Point, Ohio, HTM employs 1,100 associates and has the capacity to produce more than 1 million automatic transmissions and CVTs per year. The plant also manufactures gear sets, four-wheel-drive systems and four-wheel-drive transfer components.