SIDNEY — The Shelby County 4-H Extension is working with local manufacturing companies to provide students with applicable skills and knowledge that may give them a headstart once they enter the workforce.

The collaboration between 4-H and Sidney manufacturers manifested from Shelby County 4-H Extension Educator Cassie Dietrich’s idea to take manufacturing education to young students throughout the county. It has taken shape as an ongoing, in-school program.

The project, which Dietrich has aptly named Manufacturing FUNdamentals, is being piloted at Fairlawn and Houston schools and has been made possible by the $8,800 in grants received from the Ohio 4-H Foundation and Sidney-Shelby County Chamber of Commerce.

“This is the first time anyone in the state of Ohio in 4-H has tried to combine 4-H and manufacturing,” Dietrich said. “We have a 4-H robotics challenge, but nobody has taken it to the level of manufacturing and how that makes our everyday products.”

4-H is a network of youth organizations, which are organized and directed by cooperative extension across the country. The focus of 4-H is to give young people the opportunity to complete hands-on projects and “learn by doing.”

According to Dietrich, 4-H programs throughout Ohio are all part of the Ohio State University.

“Every state has a land grant university, which for us is Ohio State, and every land grant has extension services, which is part of the university that works out in the counties,” she said.

All 88 counties in Ohio have OSU extension offices. These offices are made up of four pillars — 4-H youth development, agriculture and natural resources, family and consumer sciences, and SNAP education.

“Each county has what’s called an educator for each one of those areas if their commissioners fund it,” Dietrich said. “For our county, (the commissioners) fund an agriculture and natural resources educator and a 4-H educator, which is me.”

“The 4-H educator’s job is to manage, run, coordinate, direct and advise the 4-H program in the county,” Dietrich continued. “So, any kid enrolled in 4-H here in Shelby County is under my reign, to a degree.”

Dietrich oversees the “traditional” 4-H programs, involving club meetings and showing animals at the fair, as well as “nontraditional” 4-H, which includes 4-H in the Classroom. This is a term for all in-school 4-H projects and programs. Dietrich’s Manufacturing FUNdamentals program is one of the latter.

Dietrich, who started as the 4-H extension educator in March, said she wrote a grant request to the Ohio State University and the Ohio 4-H Foundation after being given the substantial and open-ended task of building a stronger labor force within the county.

“When I first came here, the commissioners challenged me, because I am taxpayer-funded, to figure out how 4-H could help create a more employable workforce here in Shelby County,” she said.

Considering the prevalence of the manufacturing industry within the county, Dietrich decided to set her focus in that direction.

“We have tons of companies, and the difficulty for them is finding good employees,” she said.

Dietrich said she hopes to bridge the gap between manufacturing companies and those who will become potential employees by reaching out to children while they are young, in order to demonstrate to them from an early age that a career in manufacturing is more than just a blue collar job.

“Workforce Partnership (of Shelby County) has done a really good job of hitting the high school market, but I’m trying to focus more on third-graders as my sweet spot,” she said. “I’m trying to access the younger audience to spark an interest in having a manufacturing career, whether that’s through exploring robotics, pneumatics, hydraulics, electricity, tool and dye, metal fabrication, presses; any of that stuff you would think of when you think, ‘What’s making our cars? What’s making the can of pop that you drink?’”

“It’s really a science,” Dietrich continued. “A lot of people think of it as just a dirty job, so I’m trying to get them to understand that it’s actually a very respectable career. It’s something (they) can make a lot of money (doing), something (they) can support a family on, and it’s a very important field to be in: they’re creating the things that we’re using everyday.”

As of now, Dietrich has begun to create partnerships with Emerson Climate Technologies, Detailed Machining Inc., Airstream Factory Service Center and Stolle Machinery.

Dietrich has met with representatives from these companies in order to gain a better understanding of what their needs are within the industry, in terms of effective employment, and how 4-H could be of service to them.

With her grant request approved, Dietrich was able to start buying the tools necessary to implement the Manufacturing FUNdamentals programs within schools and engage the students in a hands-on way.

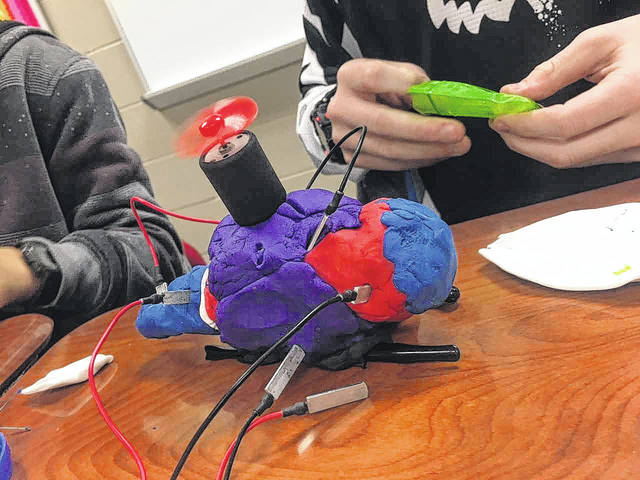

“I asked to purchase a variety of what I call desktop manufacturing applications,” she said. “They are smaller versions of what are in the big industries, (including) a laser cutter that cuts metal and engraves it, much like what they’re doing over at Airstream; a tiny, plastic injection molder that makes golf tees; a 3-D printer; LEGO robotics kits, so the kids can learn about pneumatics and robots; and Squishy Circuits — Play-Doh that makes an electric circuit — so they can learn about electricity.”

Dietrich kickstarted her program at Houston Elementary School, Jan. 4. She meets with two groups of students once a week, each for an hour at a time, and will continue to do so throughout the remainder of the school year.

Principal Sara Roseberry said she has already begun to see the positive effect the program is having on students.

“When I told them about the program, there was a lot of buzz, and they were all really excited that they were going to be participating in something that was kind of special,” she said.

Roseberry said she sees the program as a way to challenge students within the school who could benefit from a new learning opportunity, which is what helped her in the selection of the groups.

“We have a program for gifted kids, and we have a lot of high-functioning students who aren’t identified gifted that really need enrichment, so that’s how I’m using this,” Roseberry said. “I’m using it for those kiddos that work really hard and get good grades, and I just want to provide them something that will be a little more enrichment for them.”

Dietrich said the program is also underway at Fairlawn Elementary School, as of Feb. 1. Here, she is set to meet with three groups of students, each for an hour per week. She hopes to introduce the project to more schools in the coming months and years.

As for what the students are doing during these sessions, Dietrich said she has made lesson plans based around the work that is done within the manufacturing companies she has met with and involving the desktop manufacturing applications she has purchased. She plans to take volunteers from the companies into the classrooms to further explain the real-world application of the concepts students are learning.

“I can take the concepts or the fundamental things that are happening (in the factories) and I can make them kid-friendly and fun and exciting in a way that’s currently not happening,” Dietrich said. “They don’t even realize they’re learning. They think they’re just building something and having fun.”

“It’s really a true community partnership,” she continued. “It took the schools, the industry support and 4-H working together to get this in front of kids who are a litte bit younger.”

Along with the in-school course, Dietrich plans to create a 4-H project book based on the material and concepts from the Manufacturing FUNdamentals program.

Part of being a 4-H member involves completing a project, or projects, throughout the year. Project books are published as a way to explain the concepts, requirements and guidelines of each project.

By making a Manufacturing FUNdamentals project book, Dietrich would be giving all 4-H members throughout the county and state the opportunity to study and participate in her program.

Dietrich said she plans to begin the two- to three-year-long process of creating the project book this fall. She will write the book with the help of curriculum writers at OSU, as well as with guidance and ideas from the manufacuring companies regarding the content.

“I encouraged (the manufacturers) to really think about what needs to be in (the book) because I don’t know; I don’t work in a manufacturing place. They live and breathe it every day,” Dietrich said.

“My goal is basically to get them to help me build an outline of what needs to be in this book; (to) tell me what I need to know, give me the science behind it, and then I’ll turn it into a fun activity that they can do.”

Dietrich looks forward to watching her ideas for the program grow and is eager to see how the 4-H program, as a whole, can help the community.

“This, to me, is really county-wide,” she said. “It’s going to benefit the county, so it should be the county who gets behind it and gets involved in it. My door is always open to anybody who wants to figure out how 4-H can help support them.”